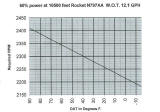

Engine and Prop

Power Chart

Hot Cylinder Cure

(Aw crap! I had a typo in the text below and had said that cylinder #1 and #5 had cooling problems due the the fin layout. It should have said cylinders #2 and #5. My apologies to anyone who was mislead by this error.)

10-17-05: An easily overlooked item that is almost guaranteed to make your Lycoming parallel valve #2 and #5 cylinders run hotter than they should is baffles that are too tight. WHAT? Yeah, too tight in certain areas. Check the photo below. Once you look at a real cylinder you'll say "Doh! Why didn't I think of that?!"

It turns out that the front of the #2 cylinder and the back of the #5 cylinder

(#3 on 4-cylinder engines)

have very shallow fins. This is fine for the other 4 cylinder positions...

they've got plenty of air flowing past them due to the way the engine is put

together. However, the #2 and 5 cylinders have a design flaw because it is

possible to put the cooling baffle on so tightly that no air can flow past part

of the cylinder. Wow... that isn't good so fix it as described in the

photo. You will be happy and your cylinders will be positively thrilled.

Cylinder Flashing

8-23-04: Lately there has been much discussion online about excess flashing in the cooling fins between the sparkplugs. It is accused of being a possible cause of high CHT's.

I don't have any data as to whether the removal of the excess material helps cooling or not.

Others have reported that the removal of the excess material took "hours and several drill bits." Yuck. A drill bit isn't a good tool for this job. Here's an easy way to rid your cylinders of the excess material. And it will take less than an hour, including removal of the spark plugs and sweeping the floor afterwards. It only takes about two minutes to do the actual filing on each cylinder.

Here's the necessary tool. An airsaw with the saw blade removed. In

place of the blade a small round file of approximately 1/8" diameter is

installed. The longer the file, the better. I used a round 6"

file with a pointed end. The pointed end is useful to get the file started

in the small crevices.

Here's the necessary tool. An airsaw with the saw blade removed. In

place of the blade a small round file of approximately 1/8" diameter is

installed. The longer the file, the better. I used a round 6"

file with a pointed end. The pointed end is useful to get the file started

in the small crevices.

You'll need to see what you're doing. I recommend this totally nerdy

cyclops light. I saw a surgeon on the Discovery Channel wearing a similar

light and instantly recognized it's worth for aircraft work. You can get

one of these LED headlight thingies at your local electronics store.... BUT it's

made to mount on your forehead and doesn't put the light where you want it.

I modified my light to mount resting on my nose. Yes, there's more to

doing this than simply turning the thing upside down. Blah, blah,

blah.... you'll figure it out if you're truly a nerd.

You'll need to see what you're doing. I recommend this totally nerdy

cyclops light. I saw a surgeon on the Discovery Channel wearing a similar

light and instantly recognized it's worth for aircraft work. You can get

one of these LED headlight thingies at your local electronics store.... BUT it's

made to mount on your forehead and doesn't put the light where you want it.

I modified my light to mount resting on my nose. Yes, there's more to

doing this than simply turning the thing upside down. Blah, blah,

blah.... you'll figure it out if you're truly a nerd.

Here's a photo of the rough casting boogers down in the cooling fins. It

certainly would seem like this cylinder would benefit from a smoother airflow

through there.

Here's a photo of the rough casting boogers down in the cooling fins. It

certainly would seem like this cylinder would benefit from a smoother airflow

through there.

Here's the same cylinder after taking the airfile to it. Much nicer.

Read the next paragraph or be sorry....

Here's the same cylinder after taking the airfile to it. Much nicer.

Read the next paragraph or be sorry....

Even though the job took less than an hour and the appearance of the cooling fins were certainly improved, there's always a downside... The air file can "grab" on the flashing and stick firmly. This causes the airfile to rattle your teeth. No harm is done UNLESS the airfile is touching one of the fragile pushrod tubes. It will dent the shit out of those tubes. Ask me how I know!! I made a nice dent on the very first try. You MUST protect the pushrod tubes by keeping your hands, BOTH of them, on the airfile. Position your hands so that if the airfile sticks you will not hit the pushrod tubes or the injection lines. If you do this you won't have any problems. Have fun! Vince

Engine disassembly

01-04: My 1100 SMOH Lycoming. I had to open the case to install the cam gear that drives the governor, so it's getting a teardown, RRAN inspection/overhaul back to 0 SMOH. Standing the engine up was the first challenge. One jug off, 5 to go.

Splitting the case. I thought you'd need that special tool that is shown

in the Lycoming manual. But Grant showed me how to use the Fred Flintstone

wooden wedges and soft mallet technique. It worked fine... but be careful

if you try this!

Miscellaneous stuff everywhere. Keep everything organized and tagged.

Much of it needs to go back in the same spot it came from.... the crankshaft for

instance. ;-)

One jug off, 5 to go.

Splitting the case. I thought you'd need that special tool that is shown

in the Lycoming manual. But Grant showed me how to use the Fred Flintstone

wooden wedges and soft mallet technique. It worked fine... but be careful

if you try this!

Miscellaneous stuff everywhere. Keep everything organized and tagged.

Much of it needs to go back in the same spot it came from.... the crankshaft for

instance. ;-)

Here are the same parts after they came back from Divco and Aircraft Specialties Services. You have to apply the paint yourself. I went down to Autozone and bought a few cans of their engine paint in red, silver, and blue. Use grease to mask off the areas that don't get painted, like the cylinder base areas. After the paint dries just wipe off the greased areas.

3-28-04: Grant Weythman helped me put the engine back

together. Grant is miking the crankshaft journals.

3-28-04: Grant Weythman helped me put the engine back

together. Grant is miking the crankshaft journals.

The bearings are inserted into the case. Next the case halves are joined

and the inside bearing diameter is measured. Everything is double checked

even though the parts were all yellow tagged and supposedly good to go.

The bummer is that when you put the case halves together, you've got to get them

back apart. We made a suitable splitter, similar to the one shown in the

overhaul manual. You'll need one too. Using a hammer and blocks of

wood to separate the case halves is not suggested, even though lots of guys do

it that way.

The bearings are inserted into the case. Next the case halves are joined

and the inside bearing diameter is measured. Everything is double checked

even though the parts were all yellow tagged and supposedly good to go.

The bummer is that when you put the case halves together, you've got to get them

back apart. We made a suitable splitter, similar to the one shown in the

overhaul manual. You'll need one too. Using a hammer and blocks of

wood to separate the case halves is not suggested, even though lots of guys do

it that way.

There's really not that much inside the engine. A crank, cam, rods, and a

few bearings are about all that is in the bottom end. Getting the bottom

end ready to close up wasn't particularly difficult.

There's really not that much inside the engine. A crank, cam, rods, and a

few bearings are about all that is in the bottom end. Getting the bottom

end ready to close up wasn't particularly difficult.

90% of your time is spent reading the overhaul manual and the parts catalog.

You absolutely must have those two books to do a decent job. Grant is

miking the cylinders and referring to the table of limits.

90% of your time is spent reading the overhaul manual and the parts catalog.

You absolutely must have those two books to do a decent job. Grant is

miking the cylinders and referring to the table of limits.

Four cylinders are back on the engine. Notice that Grant is still reading

the book.

Four cylinders are back on the engine. Notice that Grant is still reading

the book.

All six cylinders back on the engine, with the pushrod tubes too. It took

about 2 days of work to mike everything and put the parts together to get to

this point. No less that 1.8 days were spent reading the book. If

you knew what you were doing and had those books memorized you could get to this

point in a few hours, no sweat.

All six cylinders back on the engine, with the pushrod tubes too. It took

about 2 days of work to mike everything and put the parts together to get to

this point. No less that 1.8 days were spent reading the book. If

you knew what you were doing and had those books memorized you could get to this

point in a few hours, no sweat.

The accessory case is where I found several expensive problems.

There are several gears in here. They all cost $500 a piece and you can

count on several of them being shot. You'll probably spend the money since

if any of those gears breaks, it's an instant engine failure. I'm

sure that I was being overly picky, particularly since the new gears didn't

really look all that much better than the old ones!

The accessory case is where I found several expensive problems.

There are several gears in here. They all cost $500 a piece and you can

count on several of them being shot. You'll probably spend the money since

if any of those gears breaks, it's an instant engine failure. I'm

sure that I was being overly picky, particularly since the new gears didn't

really look all that much better than the old ones!

4-7-04: Oooooh, a shiny new crank gear. I also had

to find a servicable crankshaft idler gear since the one I had did not have the

fuel pump eccentric.

There's really not much hidden under the sump. Just some drain holes

and a few bolts.

The oil pump. At my mechanic's recommendation, the safety wire has a couple

pieces of Tefzel added to keep from wearing a hole in the housing.

The accessory case going back on.

Wow, valve covers are installed. That means that the valve clearances have

been double checked. I had to replace 5 pushrods with longer ones.

All of the various regrinding made the old ones too loose.

Wow, valve covers are installed. That means that the valve clearances have

been double checked. I had to replace 5 pushrods with longer ones.

All of the various regrinding made the old ones too loose.

The fuel pump is easy to install at this point. It's also easy to modify

the overflow vent as described below while the pump is on the engine.

Rather than disassemble the pump so the vent port would clear the firewall, I

did the following: the vent was plugged with a pipe plug. I had to trim

the bottom of the pipe plug to clear the hose barb. I tapped a hole

in the side of the overflow vent and installed a hose barb for the overflow

line. Be sure to put a piece of foam inside the vent port while drilling

and tapping to keep the chips out of the pump. And clean out all of the

foam and chips before the final assembly... duh. I used JB Weld to

seal/glue the hose barb in place since there is no way to safety it and my

tapped hole was just a little loose. Not shown in the picture was the

final grinding off of the pipe plug so that no excess metal was left sticking

out.

Rather than disassemble the pump so the vent port would clear the firewall, I

did the following: the vent was plugged with a pipe plug. I had to trim

the bottom of the pipe plug to clear the hose barb. I tapped a hole

in the side of the overflow vent and installed a hose barb for the overflow

line. Be sure to put a piece of foam inside the vent port while drilling

and tapping to keep the chips out of the pump. And clean out all of the

foam and chips before the final assembly... duh. I used JB Weld to

seal/glue the hose barb in place since there is no way to safety it and my

tapped hole was just a little loose. Not shown in the picture was the

final grinding off of the pipe plug so that no excess metal was left sticking

out.

Installing the sump is a breeze. Nothing but a big handful of 1/4" bolts

to put in and you're done. I also installed a sump heater for those cold

morning missions.

Installing the sump is a breeze. Nothing but a big handful of 1/4" bolts

to put in and you're done. I also installed a sump heater for those cold

morning missions.

Ready to hang back on the plane.

Ready to hang back on the plane.

If John would get out of the way, I could put the engine back on.

If John would get out of the way, I could put the engine back on.

It's important to keep the tail weighted down so that the engine doesn't turn

your fuselage into a teeter-totter. An old useless starter makes a perfect

weight.

It's important to keep the tail weighted down so that the engine doesn't turn

your fuselage into a teeter-totter. An old useless starter makes a perfect

weight.

Here's a shot of Mark Landoll's alternator. Details are on the electrical

page. It fits up nice and tight to the engine.

Here's a shot of Mark Landoll's alternator. Details are on the electrical

page. It fits up nice and tight to the engine.

John works on the wiring, but I'm still admiring the prop.

John works on the wiring, but I'm still admiring the prop.

And the cowling even fits! This matter was in question since I had never

actually had the prop on before.

And the cowling even fits! This matter was in question since I had never

actually had the prop on before.

The top cowling fits also. If you look closely you can see that the prop

sticks up just a wee bit above the cowling (as planned). If the mounts sag

a little like they should, everything will fit perfectly. If not, a few

washers will fix it.

The top cowling fits also. If you look closely you can see that the prop

sticks up just a wee bit above the cowling (as planned). If the mounts sag

a little like they should, everything will fit perfectly. If not, a few

washers will fix it.

The Superior Dance, shamelessly stolen from the "Church Lady" on SNL. We

do it much better.

The Superior Dance, shamelessly stolen from the "Church Lady" on SNL. We

do it much better.

4-22-04: The fuel pump is TIGHT, just like you've been warned. See pic

above for mods.

4-22-04: The fuel pump is TIGHT, just like you've been warned. See pic

above for mods.

The Airflow Performance pump WILL fit in the same bay as the control stick with

plenty of room left over to mount the Navaid servo on the right side of the

stick. As you can see, a couple of extra holes were drilled in the

sidewall for that pesky loop of tubing to stick through.

The Airflow Performance pump WILL fit in the same bay as the control stick with

plenty of room left over to mount the Navaid servo on the right side of the

stick. As you can see, a couple of extra holes were drilled in the

sidewall for that pesky loop of tubing to stick through.

BTW, the bay forward of the stick is occupied by a large glovebox which is the

reason for shoehorning the fuel pump in next to the stick. Valuable real

estate must not be wasted!

BTW, the bay forward of the stick is occupied by a large glovebox which is the

reason for shoehorning the fuel pump in next to the stick. Valuable real

estate must not be wasted!

Sharp eyed readers will say to themselves "Wow, how did he bend that one piece

of tubing in the corner so tightly? He must be SUPERMAN! My bender

won't get that close to the fitting and I always kink it when I use my fingers."

Sharp eyed readers will say to themselves "Wow, how did he bend that one piece

of tubing in the corner so tightly? He must be SUPERMAN! My bender

won't get that close to the fitting and I always kink it when I use my fingers."

Well, there are other ways to bend tubing than with one of those shitty benders. Get a pound of CERROBEND from your wife who works in radiation therapy at the local hospital. Other low melting alloys or even packed sand will work. Sand sucks to work with, but CERROBEND, which melts at 225 degrees F is perfect.... except for the toxic lead fumes.

It's pretty obvious from the pictures, but first you flare the tubing on both ends after you install the fittings! Then pour in the molten CERROBEND. Cool and bend carefully. Reasonable bends are easy but it is possible to crack the aluminum if you get too aggressive. Simply remelt the CERROBEND while being careful not to overheat the aluminum. The CERROBEND will come right out. Clean the tubing like you would any other before you install it.

Engine baffles:

There are many ways to make your engine baffles. Several are shown below. Here's what I did:

5-17-04: I had plenty of leftover .032 aluminum, a set of

Jack Gray's baffle templates printed out, and an empty checkbook so I decided to

make my own baffles. A tedious job for sure, but not any worse than any of

the 101 other tedious jobs done so far.

5-17-04: I had plenty of leftover .032 aluminum, a set of

Jack Gray's baffle templates printed out, and an empty checkbook so I decided to

make my own baffles. A tedious job for sure, but not any worse than any of

the 101 other tedious jobs done so far.

Since I wanted a fully enclosed plenum, I knew that some modifications were needed to Jack's drawings. I started out by cutting out all of the paper templates. I soon realized that either I am an idiot or that some of the drawings weren't quite right for my engine. I'm not sure which, but either way I needed to make a few of the rear templates out of cardboard.

As you can see in the photos, it's important to obtain the stiff cardboard from your daycare's leftover bin. That way you'll have plenty of flowers already drawn on the cardboard. :-)

Like I said, I had no luck figuring out how the rear wall of the baffles fit

together, so I made my own using Jack's drawings as a guide.

Like I said, I had no luck figuring out how the rear wall of the baffles fit

together, so I made my own using Jack's drawings as a guide.

6-2-04: The plenum sides are taking shape nicely. So far everything

looks good... even if it's not quite to the final shape yet.

6-2-04: The plenum sides are taking shape nicely. So far everything

looks good... even if it's not quite to the final shape yet.

The inlets were shaped so that they would match the holes in the cowl.

They will get a serious trimming later after everything else is finished.

Right now they are more for holding the other stuff in place. They aren't

very aerodynamic in this boxy form.

The inlets were shaped so that they would match the holes in the cowl.

They will get a serious trimming later after everything else is finished.

Right now they are more for holding the other stuff in place. They aren't

very aerodynamic in this boxy form.

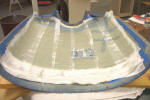

6-3-04: Someone had the brilliant idea to use the

top cowl as a female mold to make a fiberglass top for the plenum. I had

to try it.

6-3-04: Someone had the brilliant idea to use the

top cowl as a female mold to make a fiberglass top for the plenum. I had

to try it.

I used clear, sticky backed carpet protector (like a contractor puts down in a new house to keep the carpet clean) to protect the cowl from the resin. It works OK, not good, but OK. It peels off easily, but is tough to get to lay down without creases. Next time I'd just use 2" wide painter's masking tape, the kind that comes off easily. Whatever you use, be sure to brush a layer of Partall mold release on top so the resin won't stick.

A layer of resin gets brushed in and the first of 6 layers of BID cloth goes in.

A layer of resin gets brushed in and the first of 6 layers of BID cloth goes in.

John stipples the bubbles out.

John stipples the bubbles out.

A layer of peel ply neatens up the inside.

A layer of peel ply neatens up the inside.

Hey, it fits. Well, good enough to be a decent starting point

anyway.

Hey, it fits. Well, good enough to be a decent starting point

anyway.

Need to remove the tape that is still stuck in place.

Need to remove the tape that is still stuck in place.

Voila! A few minutes of trimming and we'll be in business!

Voila! A few minutes of trimming and we'll be in business!

Making a "mold" using tape, cardboard, dead animals, heavy paper, whatever is

handy! When Long Eze builders look at my fiberglass work, their jaws

always drop. I guess they're impressed. I'm impressed that anyone

would build anything out of this sticky, carcinogenic crap.

Making a "mold" using tape, cardboard, dead animals, heavy paper, whatever is

handy! When Long Eze builders look at my fiberglass work, their jaws

always drop. I guess they're impressed. I'm impressed that anyone

would build anything out of this sticky, carcinogenic crap.

Adding a flange around the edges and filling the ugly work I'd done on the top

piece.

Adding a flange around the edges and filling the ugly work I'd done on the top

piece.

6-15-04: Everything was going well until Murphy

showed up and reminded me that the cowl clearance is tight...REALLY TIGHT....

above the #1 cylinder. The beautifully molded fiberglass masterpiece that

I slaved over hit the cowl top. DOH! Not bad, but bad enough that it

needed to be lowered (pictures to come later). In this picture the arrow

points to the area that is about an inch too tall!!!! DOH!

6-15-04: Everything was going well until Murphy

showed up and reminded me that the cowl clearance is tight...REALLY TIGHT....

above the #1 cylinder. The beautifully molded fiberglass masterpiece that

I slaved over hit the cowl top. DOH! Not bad, but bad enough that it

needed to be lowered (pictures to come later). In this picture the arrow

points to the area that is about an inch too tall!!!! DOH!

I'll post more pictures of that later, but trust me here, if you're building a plenum like this it MUST be so close to the #1 spark plug that you can't get the wire on. Yup, that close. I had to make a 90 degree in the spark plug wire about 3/8" above the spark plug (pictures to come later). Japundza tells me that you can get shorter spark plugs. REM37BY from Van's. I have no clue if they'd be short enough or not. Too late for me though.

Final fit and fill (not anymore!!!! I wasn't happy

with the way the right inlet was looking so I remade it. See below.)

Final fit and fill (not anymore!!!! I wasn't happy

with the way the right inlet was looking so I remade it. See below.)

The piece is painted using Rustoleum Hammered

Finish silver paint. It works very well and fills the weave well also.

In fact, it worked so well that I plan to paint the inside of the cowling with

it.

The piece is painted using Rustoleum Hammered

Finish silver paint. It works very well and fills the weave well also.

In fact, it worked so well that I plan to paint the inside of the cowling with

it.

7-21-04: The governor cable passes through my plenum... an annoying design flaw

on my part, but one that I'll live with because I want to get this thing in the

air this year. The little gap seals are made from baffle material

and are slit into tiny slivers sorta like a comb. This allows the rod to

move freely, yet helps block some of the air leakage. It's not the most

cosmetically beautiful work I've ever done but it seems to work well.

7-21-04: The governor cable passes through my plenum... an annoying design flaw

on my part, but one that I'll live with because I want to get this thing in the

air this year. The little gap seals are made from baffle material

and are slit into tiny slivers sorta like a comb. This allows the rod to

move freely, yet helps block some of the air leakage. It's not the most

cosmetically beautiful work I've ever done but it seems to work well.

9-2-04: I wasn't happy with the opening of the right

inlet. The aluminum kluge that I had cobbled together just didn't look

like there was enough room to flow any air. What to do??? Get the

airsaw and do some serious surgery, foam the vacant hole, then shape a new,

improved plenum inlet.

9-2-04: I wasn't happy with the opening of the right

inlet. The aluminum kluge that I had cobbled together just didn't look

like there was enough room to flow any air. What to do??? Get the

airsaw and do some serious surgery, foam the vacant hole, then shape a new,

improved plenum inlet.

After trimming to foam, you fill it with Bondo. (Please note that this is

the only acceptable use for Bondo anywhere on the airframe, IMHO.)

After trimming to foam, you fill it with Bondo. (Please note that this is

the only acceptable use for Bondo anywhere on the airframe, IMHO.)

After the Bondo is nice and smooth, you brush on several coats of PVA mold

release. Wicks sells it.

After the Bondo is nice and smooth, you brush on several coats of PVA mold

release. Wicks sells it.

Well, well, now that's a much more nicely shaped inlet than before!

Well, well, now that's a much more nicely shaped inlet than before!

The initial trim looks like it might even fit.

The initial trim looks like it might even fit.

The left inlet will stay as is.... for now anyway. The left inlet seems to

have a fairly smooth path for the air to enter the plenum. As you can see,

the prop governor is above the plenum entrance. If it doesn't work, I'll

simply redo this side to match the other side. That will put the governor

in the air stream.... is that good or bad??? Time will tell.

The left inlet will stay as is.... for now anyway. The left inlet seems to

have a fairly smooth path for the air to enter the plenum. As you can see,

the prop governor is above the plenum entrance. If it doesn't work, I'll

simply redo this side to match the other side. That will put the governor

in the air stream.... is that good or bad??? Time will tell.

OIL COOLER:

7-21-04: Given the HOT reputation of the Rockets, I wanted to maximize my oil

cooling right form the start. I decided to give the Cool Collar a try.

For $30, what the heck. That's almost free in airplane dollars.

7-21-04: Given the HOT reputation of the Rockets, I wanted to maximize my oil

cooling right form the start. I decided to give the Cool Collar a try.

For $30, what the heck. That's almost free in airplane dollars.

I don't know if everyone else does it this way or not, but in my opinion you'd be wasting your time to install one of these without first applying a good dose of silicone heat sink compound to transfer the heat. The silicone is rated to 400 degrees F, so the oil temps certainly won't hurt it. It is messy, but probably well worth it.

Here's the Cool Collar installed after I cleaned out all of the oozing silicone

heat sink compound. Even with the completed oil cooler in the way (see

below) and all of the hoses/plug wires installed, I can still remove the oil

filter WITH the Cool Collar installed quite easily. I'll report later as

to whether it actually helps to cool the oil.

Here's the Cool Collar installed after I cleaned out all of the oozing silicone

heat sink compound. Even with the completed oil cooler in the way (see

below) and all of the hoses/plug wires installed, I can still remove the oil

filter WITH the Cool Collar installed quite easily. I'll report later as

to whether it actually helps to cool the oil.

I did get a face to face PIREP from a Pitts driver who reports that he used this exact technique on his Pitts and got a 10 degree drop in oil temps. He used the silicone heat sink compound to transfer the heat also.

7-21-04: I didn't want my oil cooler robbing air from the rear cylinders, so I

mounted it in the middle. This was possible because I don't have a vacuum

pump or a tach cable in the way. This also allows easier access to the

back of the engine since the cooler is relatively high up and not cluttering up

the space behind one of the cylinders. More on this later as I'm

still working on it.

7-21-04: I didn't want my oil cooler robbing air from the rear cylinders, so I

mounted it in the middle. This was possible because I don't have a vacuum

pump or a tach cable in the way. This also allows easier access to the

back of the engine since the cooler is relatively high up and not cluttering up

the space behind one of the cylinders. More on this later as I'm

still working on it.

8-19-04: Here's a shot of the completed cooler setup.

The plan calls for the air to smoothly enter the ramp into the cooler plenum,

move through the cooler, then blow past the Cool Collar that shrouds the oil

filter. The ramp is made to be flexible when the engine moves

around. He he he....what could possibly go wrong??? Bwaaa ha ha ha ha!

8-19-04: Here's a shot of the completed cooler setup.

The plan calls for the air to smoothly enter the ramp into the cooler plenum,

move through the cooler, then blow past the Cool Collar that shrouds the oil

filter. The ramp is made to be flexible when the engine moves

around. He he he....what could possibly go wrong??? Bwaaa ha ha ha ha!

The second photo shows the cover setting in place but not screwed down. The front edge of the cover is made from cowl baffle material since the oil cooler and the engine need to move independently.

Fuel injection:

7-21-04: Bits of the throttle/mixture cable bracket.

7-21-04: Bits of the throttle/mixture cable bracket.

The bracket installed! Woo hooo! It works.

The bracket installed! Woo hooo! It works.

The flow divider was a bit of a problem to mount. Apparently the flow

divider bracket that I have was intended for a Lycoming with a bolt hole boss in

the side of the case. There seemed to to be nowhere to bolt the darned

thing on! I had to fabricate a new flow divider mount, as seen here.

The flow divider was a bit of a problem to mount. Apparently the flow

divider bracket that I have was intended for a Lycoming with a bolt hole boss in

the side of the case. There seemed to to be nowhere to bolt the darned

thing on! I had to fabricate a new flow divider mount, as seen here.

The original mount was to be offset to the right while the new mount was designed to mount on the engine centerline. This meant that some of the brand new injector lines were too short. I had to order two new lines.

I probably went overboard on the "anti-vibration" silicone RTV near the flow divider, but since one Rocket crash was attributed to the fatigue if one of these lines, I feel better about it.

I noticed on Mark Frederick's new F-1 that he had a nice rolled edge on the

outlet for his cooling air. He said it helped the cooling. Although

I had intended to put one on there anyway, his comments sealed the decision.

Should reduce drag too. We'll see! I made my

"flow-smoother-outer/drag-reducer" from .016" aluminum. Very easy to do.

I added a cover for the fuel line hole after the fuel line was installed.

I noticed on Mark Frederick's new F-1 that he had a nice rolled edge on the

outlet for his cooling air. He said it helped the cooling. Although

I had intended to put one on there anyway, his comments sealed the decision.

Should reduce drag too. We'll see! I made my

"flow-smoother-outer/drag-reducer" from .016" aluminum. Very easy to do.

I added a cover for the fuel line hole after the fuel line was installed.

Shown here and in the photos above is the Vetterman exhaust installation.

His stuff is great. It's one of the VERY few items that you can buy and

actually bolt it on WITHOUT any modifications. Takes about an hour or two,

including the hangers and EGT probes. You do have to drill the holes for

the EGTs. I installed my EGT probes 4.5" from the exhaust flange so

they would all be in a straight section of the pipe... or close. This

seemed like a good compromise as there is no perfect spot.

Shown here and in the photos above is the Vetterman exhaust installation.

His stuff is great. It's one of the VERY few items that you can buy and

actually bolt it on WITHOUT any modifications. Takes about an hour or two,

including the hangers and EGT probes. You do have to drill the holes for

the EGTs. I installed my EGT probes 4.5" from the exhaust flange so

they would all be in a straight section of the pipe... or close. This

seemed like a good compromise as there is no perfect spot.

Completed engine (Well 99.9% anyway) photos:

9-10-04: Well, I think that the engine is ready to go to the airport. There's still work to be done, of course, but it's minor stuff like making heat shields for the exhaust, timing the mags, and checking fuel flows. Overall, I am quite pleased with the way everything went together, even though my baffles and plenum are some of the ugliest work on the entire plane. Heck, they're not that bad, just not as professional looking as I would like them to be.

Even if the plenum is not a "10" it looks like it should do its job nicely. I am pleased with the look of the inlets and outlet. They "look" like they should flow air with minimal turbulence. Time will tell!!

The oil cooler still needs an airflow control gate of some sort, but I'm not going to waste any effort on that until it proves that it can cool the oil! IMHO, having the oil cooler mounted in the center makes access to the back of the engine a breeze. I am quite pleased with this location... assuming that the oil cools properly. At least one person who seems to be knowledgeable assured me that the center location was a good choice since it doesn't rob cooling air from a single cylinder. Cool. That was one reason I chose the center location.

Prop:

9-17-04: You need to check the blade tracking even on a zillion dollar new prop. The round ends of the blades make it more difficult to "eyeball" the same spot on each blade, hence the ruler. The blades should track to within an 1/8" of each other... or less.

I used Mark's spinner cutout template to mark the blade holes. As you can

see in the pictures below, the aft end of the cutout is narrower than the

blade. This means that you need to twist the blades to install the

spinner. It's difficult to turn the blades, hold them in coarse pitch,

and install the spinner with only two hands. The boards clamped to the

blade allowed me to put my calf behind the blade and hold them in coarse pitch

while my hands installed the spinner.

I used Mark's spinner cutout template to mark the blade holes. As you can

see in the pictures below, the aft end of the cutout is narrower than the

blade. This means that you need to twist the blades to install the

spinner. It's difficult to turn the blades, hold them in coarse pitch,

and install the spinner with only two hands. The boards clamped to the

blade allowed me to put my calf behind the blade and hold them in coarse pitch

while my hands installed the spinner.

An airsaw makes a nice cut, even on parts that are already painted. Yeah,

I had to sand the rough edge, but it looks fine to me. (I did all of the

painting last September before the cold winter weather arrived. You can't

let the fear of a few scratches stand in the way of progress. Actually,

if you use decent paint and are careful, you won't scratch anything anyway.

I didn't. Really, no scratches anywhere.)

An airsaw makes a nice cut, even on parts that are already painted. Yeah,

I had to sand the rough edge, but it looks fine to me. (I did all of the

painting last September before the cold winter weather arrived. You can't

let the fear of a few scratches stand in the way of progress. Actually,

if you use decent paint and are careful, you won't scratch anything anyway.

I didn't. Really, no scratches anywhere.)

The rough cutout. The hard part is putting the other one EXACTLY 180

degrees away.

The rough cutout. The hard part is putting the other one EXACTLY 180

degrees away.

Checking the spinner for wobble. The pen should make a dot, not a circle!

The hub of my prop required three layers of UHMW tape to remove the slack where

the spinner slips over the hub. Make sure that your spinner doesn't

wobble!!! Do this before you add the screw holes to the

backplate!!! NO WOBBLE ALLOWED!

Checking the spinner for wobble. The pen should make a dot, not a circle!

The hub of my prop required three layers of UHMW tape to remove the slack where

the spinner slips over the hub. Make sure that your spinner doesn't

wobble!!! Do this before you add the screw holes to the

backplate!!! NO WOBBLE ALLOWED!

Since I had striped my spinner, I checked their track too. What do you

know, they were right on.

Since I had striped my spinner, I checked their track too. What do you

know, they were right on.

You gotta fill in the gap with the piece that you took out. Well, you

don't have to fill it in, but it looks much better this way.

You gotta fill in the gap with the piece that you took out. Well, you

don't have to fill it in, but it looks much better this way.

Here's the gap filling pieces with the JBWELDED doublers. The SOFT

rivets are mainly to hold the parts together while the JBWELD sets.

Here's the gap filling pieces with the JBWELDED doublers. The SOFT

rivets are mainly to hold the parts together while the JBWELD sets.

Likewise, these parts are then JBWELDED to the backplate. The screws are

there to hold the parts while the JBWELD sets.

Likewise, these parts are then JBWELDED to the backplate. The screws are

there to hold the parts while the JBWELD sets.

After drilling the spinner for the screws that will hold it to the backplate,

add the nutplates to the backplate. Also in this shot you can see the

rivets that hold the doubler to the backplate near the bolt holes. A

large area washer is also used here.

After drilling the spinner for the screws that will hold it to the backplate,

add the nutplates to the backplate. Also in this shot you can see the

rivets that hold the doubler to the backplate near the bolt holes. A

large area washer is also used here.

Mark recommends a doubler to strengthen the carbon fiber. Here's one way

to do it. They are also JBWELDED to the backplate, with pop rivets to

pull 'em tight.

Mark recommends a doubler to strengthen the carbon fiber. Here's one way

to do it. They are also JBWELDED to the backplate, with pop rivets to

pull 'em tight.

If you put a straight edge on the backplate flange you might find that it is

not flat. Use a file to take most of the bumps off. As you can see

in the photo, there is a depressed area right down the center. I chose to

fill it with a strip of 3M fine line tape.

If you put a straight edge on the backplate flange you might find that it is

not flat. Use a file to take most of the bumps off. As you can see

in the photo, there is a depressed area right down the center. I chose to

fill it with a strip of 3M fine line tape.

Next a strip of 3M masking tape covers the entire area. The idea is that

the tape will smoosh out any other imperfections AND tighten up the fit.

You want that spinner to fit tightly! NO WOBBLE ALLOWED!

Next a strip of 3M masking tape covers the entire area. The idea is that

the tape will smoosh out any other imperfections AND tighten up the fit.

You want that spinner to fit tightly! NO WOBBLE ALLOWED!

Then you put the screws in and step back to admire your work. I used

countersunk screws and washers for a smoother fit.

Then you put the screws in and step back to admire your work. I used

countersunk screws and washers for a smoother fit.

This shot shows the extra washers needed to space the carbon fiber backplate

away from the prop hub. Mark suggested doing this, although the Hartzell

manual says only 2 washers are allowed. Mine took 4 regular thickness

washers and 1 thin washer to get the backplate to clear the hub.

This shot shows the extra washers needed to space the carbon fiber backplate

away from the prop hub. Mark suggested doing this, although the Hartzell

manual says only 2 washers are allowed. Mine took 4 regular thickness

washers and 1 thin washer to get the backplate to clear the hub.

More on the prop/spinner spacing:

Mark,

I seem to recall that you said that I would need slightly longer bolts through my prop hub to hold the spinner backplate. Is that correct? Right now I have 5 washers installed to give 1/32" clearance between the prop hub and spinner backplate. Does that sound about right?

The AN6-46 bolts that I purchased for this task are about 0.001" fatter than the bolts that I took out of the hub. They would go in with persuasion. However, the prop hub bolts have markings on them that make me suspicious that they aren't regular AN bolts and I hate to put AN bolts in there without asking someone with a little more experience here. Vince (THEY AREN'T REGULAR AN BOLTS! See below.)

Contact Kevin Karam at Hartzell for prop questions - 1-800-942-7767 Cheers mark

John at Hartzell product support says that they have a longer bolt, p/n A1584 (5.1" grip length) to replace the bolt, p/n A3207 (grip length 4.5") that comes in the HC-M2YR-1BF-F8475D-4 prop.

John from Hartzell later called me back and said that they had a 4.7" long bolt, p/n A-3203 available.

I asked about using AN6-46 bolts instead of the Hartzell bolts, which look identical. John said he can't officially bless the use of anything other than their hardware, but he did say that the hub clamping bolts that hold the spinner backplate do not hold the hub together. They are there to hold the spinner backplate.

The longer Hartzell bolt is .35" longer than

the AN6-46 bolts that I had. The AN6-46 would be a very tight fit as they

measured 0.001" fatter than the Hartzell bolts. Putting the AN bolts in the

freezer for a few minutes might work... but still a

malletization would be required. The other option is to carve a

relief notch out of the spinner backplate and use the standard bolts. Mark

can chime in on the suitability of doing this.

Vince (Mark says

not to chop up the spinner.)

From: Bob Japundza

Sent: Monday, April 26, 2004 11:14 AM

Subject: RE: prop bolts

Been there done that.

The longer Hartzell bolts were at the time $24.00 apiece. I was told these

bolts are x-rayed, even the new ones. These bolts have a unique marking on

them, made for Hartzell. (IIRC they're stamped with a triangle with an "H" in

the middle).

I don't know how it could be possible that those bolts don't hold both halves of the hub together, since the shanks of the bolts goes thru both halves of the hub and they're torqued to the Hartzell spec which is shown in the overhaul manual which I have a copy of.

Regards, Bob

I asked John, the Hartzell guy, about the bolts and their relationship to holding the blades in. He said that they are to hold the spinner backplate, not the blades, even though they definitely appear to be in a good spot to support the blades, IMHO too.

We discussed what would happen if the carbon fiber backplate got crushed, damaged, melted, termites ate it off, whatever, and he said that would create other problems (like lots of noise and vibration) but the blades would be remain. It seems to me that the carbon fiber backplate would be the strength limiting item in the stack of parts in question. If it fails then the bolt will be loose and fail anyway.

$24 per bolt does seem a bit steep... unless you've recently bought connecting rod bolts.

Mark did mention, as I remembered from earlier, that trimming the backplate is not the best idea in his opinion.

I'm just reporting what I was told... hell, I could have been talking to the Hartzell janitor for all I know. YMMV Vince

FWIW, I talked recently about the spinner backplate / hub clamping bolts that were too short. I've got some more info for those who are using the 2 blade prop.

I noticed that the torque specified for the Hartzell bolt, 22 footpounds, is higher than the torque that we would normally put on an AN6 bolt, 16 foot pounds. Hmmmm.

5-01-04:

Not being all warm and fuzzy about using a non-specified bolt, I decided to get the proper bolt. I called Hartzell and they don't stock the A-3203 that is needed. What? I called several other prop shops.. no luck. Finally, Ottosen Propeller in Phoenix, AZ had them in stock. You can call them at 1-800-528-755. They are $38 each.Then in a fit of curiosity, I decided to see what I was getting for $38 each. I took one of the short hub bolts that I can't use, actually I took all 4 of them, down to the engineering materials lab. It is in this lab where metal meets its doom. Not content to destroy only $38 bolts, I also grabbed a couple AN bolts, and a couple old Van's prop hub bolts. If you've built an RV with a wood prop you'll remember the 6.5" bolts that hold the prop on.

The tensile testing is fun. Lots of non-action followed by "BANG" as the bolt breaks. Of course, you can stop the test when the bolt silently yields….but what fun would that be?

Results:

# bolt type diameter Brinell hardness tensile strength (raw number) PSI (if I calculated correctly)

1 Hartzell A3207 . 3705 201 17500 162,000

2 Hartzell A3207 . 3705 201

3 AN6 .3725 201 15000 137,000

4 AN6 .3725 197

5 RV-prop .3725 174 14200 130,000

6 RV-prop .3725 192

What does all of this mean? Is the extra tensile strength worth $38 each? Who knows? Besides I only tested one sample and have no idea what the variability is. It's just for grins.

YMMV,

Vince

Tom Martin's spinner trimming pictures. *end of comment*

5/19/03: I made the switch this weekend from my Hartzell 2 blade to the MT 3 blade and have performed some initial performance comparisons. I have accurately and repeatedly documented my 2 blades performance at 10,000 feet, full throttle and 2100 RPM leaned 50 rich of peak. What I had at 10K was MP 21.3 WOT, 2100 RPM, 11.7 GPH , and 204-205 knots.

With the 3 blade MT I now have MP 21.3 WOT, 2100 RPM, 11.7 GPH, and 200-201knots. I think I can confidently say the MT is slower in cruise by about 3-5 knots. Also acceleration on takeoff, while still breathtaking, is not as strong as before. This is just a subjective comment done by feel. Climb rate seems about the same, but who knows, I just know it still puts the RV-8s to shame. Deceleration actually seems better with the MT, possibly because it is flattening out more. I like deceleration as much I like to go fast.

Now for the really good news. I'll just sum it up with two words, VERY SMOOTH. Its like a different airplane, I think I put an electric motor on the front. It is smooth across the power band, exactly what I was looking for.

The MT 3 blade spinner is approximately 3/16 closer to the cowl than the 2 blade spinner, but thankfully I set my spinner gape at about 3/8 to the 2 blade spinner, so my gap is now about half what it was but it looks real good, maybe even better. The new MT spinner complements the lines of the aircraft nicely, very similar to the Hartzell spinner in shape. This was a bolt off, bolt on mode, very simple.

Thanks Mark for making it all possible. Greg Nelson N144X *end of comment*

I have in my notes that a Hartzell HC-M2YR-8475D-4 will fit. M2YR is the extended, hard-to-find hub. I think others have used a C2YK hub and an appropriate prop extension. *end of comment*

We do not have any G-Limits on our propellers, with any hub used. The latest configuration for the F-1 Rocket, designed in cooperation with Mark Fredrick is:

Propeller MTV-9-B/198-52 with Spinner P-810-A.

The hub is a 172 mm extended version, but since we have a different hub design, not comparable to any Hartzell designated extension. For the Harmon Rocket, it could be possible to use a different spinner, because we assume a different cowling is used, but the deviation shall be minor. Best regards Gerd R. Muehlbauer President MT-Propeller Entwicklung GmbH

I sell the prop + spinner for $8750. Shipping is not quite straightforward, though. You can have an un-assembled prop shipped to an assy shop near you, and you can then drive over & pick it up. Shipping in this case runs about $250, and assy about $300. Shipping the assembled prop direct will set you back about $1100 (shipping, customs, etc).

FY2003 pricing on the 3 blade Hartzell w/composite spinner looks to be about $8500 with shipping about $200 or so. So, the prices are not that far apart. The Hartzell weighs about 75 lbs w/spinner; the MT closer to 52 lbs. Cheers! Mark *end of comment*

Scott Stambaugh's governor cable installation.

Scott Stambaugh's governor cable installation.

Here are a couple of pics of my governor installation. Note that I used a 60" cable which is a bit on the short side. The use of the 60" cable that Mark supplies will allow you to move the bracket closer to the centre line of the engine and towards the cooler side of the cylinders. I had to mount the ball joint on the outside of the governor arm, with the longer cable we may be able to mount it on the inside of the governor arm.

Note that the bracket is constructed of .063 aluminum angle and the "arm" that the cable is attached to is 1/8", 4130 plate. I use two independent safety wires to hold the cable in place. I have used variations of this set-up on three planes, this one seems to work pretty good.

I really like the little governor! You will likely have to drill a hole higher on your quadrant to get enough movement of the cable to swing the governor arm through the full arch. Tom Martin *end of comment*

Jack Gray sent these drawings of his engine baffles. You should be able to print them out and use them as guides to manufacture a set of baffles. Print one out and check for proper size before you print them all.

Jack Gray's Baffle drawings\baffle_templates.pdf

And some photos too.

Here's Stu Smith's HRII engine installation and cowling.

Bill Tew's plenum under construction.

The last 3 pics: Here's the initial fit up

of Craig Lefever's baffle kit on my F1, took about 1/2 hr to get everything

lined up for assembly. Fit and quality is outstanding. Highly

recommended. Eric Hansen F-1 #45 Contact info: Tucson, AZ , 520-603-0768 , Craig

Lefever, feeve80@aol.com *end of comment*

The last 3 pics: Here's the initial fit up

of Craig Lefever's baffle kit on my F1, took about 1/2 hr to get everything

lined up for assembly. Fit and quality is outstanding. Highly

recommended. Eric Hansen F-1 #45 Contact info: Tucson, AZ , 520-603-0768 , Craig

Lefever, feeve80@aol.com *end of comment*

Q: Bart,

Mark Frederick suggested that I ask you this question. I am getting conflicting info on the RPM limit for a Lyc IO-540-C4B5. The TCDS and Lycoming say 2575 is the redline for this engine. The prop shop, governor shop, and others (well known Rocket builders) claim 2700 is no problem.

I'd prefer to have the option of 2700RPM so I can keep up with the other Rockets! What do you recommend as a redline for this engine?

Thanks, Vince

A: Vince,

The C4B5 can be turned at 2700 RPM safely. The speed change is the main difference between the IO-540-C4B5 and the 260 HP IO-540-D4A5. Aero Sport Power , Bart

Can you tell me what the normal operating range would be for:

fuel pressure

Don Rivera tells me that about 45PSI is a reasonable redline, with about 15 on the bottom end. I think there is data in the Lyc manual here...

oil temp

Green to the 245F redline. Some put a yellow line below 100F.

and oil pressure

Uh...I think about 30 on the bottom, and 100 on the top, with a green range at 70 to 90. Consult your Lyc manual here

Also want to confirm that Vmax cruise is 160kts. Correct?? Thanks

Top o' the green is indeed 160KT IAS. Yellow up to 239, with the redline at 240KT. Cheers, Mark

Here is what I "think" are the correct ranges. Someone please correct me if these are not right:

White Arc: 52 KTS to 95 KTS

Green Arc: 60 KTS to 160 KTS

Yellow Arc: 161 KTS to 239 KTS

Red Line: 240 KTS

New Lyc's from the factory have a 115psi OP redline.

A while back there was discussion on turning up the pressure in regards to the #5 cyl. not getting enough oil due to the galley design. If Lycoming is cranking up the pressure then we should take note of that. Its 115psi if you take pressure off the front, 125psi if you take it off the back of the engine Correct, and I talked to the fellas who wrote the article. They noted that the increased oil press was to help with increasing the flow, which was to help with cooling the heads....which we don't really need if our head temps run cooler than 370-380F, according to the writers.

The older Lycs still use a lower upper limit: 95PSI is noted in this manual, with 55PSI as the min (in cruise) and 25PSI as min idling.

In addition (newer versions), the pressure pick-off is at the front of the engine, so line pressure would be considerably higher.

Oddly enough, a different design lifter -- with a higher leak-down rate, somewhat newer than the 1929 Cadillac design in use in most Lycomings, would obviate the necessity for higher pressures. But we're still running magnetos, so I doubt the lifters will be updated.

Cheers, Mark

We used the CAFE data from John Harmon's testing. I seriously doubt the testing was done at gross weight -- probably as light as possible, actually. In addition, they use 15"MP/1500RPM in the test, which is about run-up power on our birds -- quite a bit, if you ask me. Typical stall on my ship shows about 60 kts if you're working it carefully, and about 85 kts if you're doing wifferdills and pulling some amount of G. I didn't test at any higher G loadings. If your ship indicates a 44KT stall, we still have to do some side-by-side flying to see what the heck is going on! Not that it's not possible, mind you, but I'd sure like to see it. Carry on! MarkEngine:

This is a U channel piece. I had to use a plate nut on the inner as it came out under my quadrant mount. Bob WahlQ: What cables should I get for throttle, mixture and prop?

A: Mark provides the cable kits. I believe the throttle and mixture are 60" and the prop is 66". These are the standard 920 push pull cables. Tom Martin

11-2005: Jim Stone's HRII engine installation.

11-2005: Jim Stone's HRII engine installation.

Pictures of John Wach's engine installation.

Pictures of David Howe's engine installation.

David has a fine installation. Every time I look through these pics I see something cool that I didn't notice before. It appears that he used heat shrink tubing to seal the ends of his firesleeve. Everything is cad plated. The cooling plenum looks great. It appears that he made some mods to the firewall, weldments, and engine mount/gear leg area. I wish I'd muscled through the crowd to ask him, but he was overwhelmed the instant he started to remove the cowl.

Above are some pictures from last year's John Harmon fly-in of the very first Massey installation of their round-inlet cowl clip. Very nice with the Dave Anders polished aluminum inlet rings. There are also a couple of pictures of the same aircraft with the cowl removed, showing the pressure plenum top and the ram air filter tube.

Other miscellaneous pics....

John Harmon's exhaust pipes on Jim Stone's Rocket

Fuel fittings on firewall: Be careful not to mount the fitting too low. Ideally you do not want there to be a low spot in the fuel system that could trap water. Run the line straight forward from the boost pump. I use a bulkhead fitting at this location. Note that this is a good location to put a thick "washer" or spacer on the fitting to stiffen the firewall. Attached are two pics, I hope this is not a problem for people. Tom Martin *end of comment*

Hey Fellas:

I found the big catalog this AM; Lyc fuel pump fittings are as follows:

90 deg P/N 50ERC006-B979 $2.19 ea

Straight P/N 50GSM006-B979 $1.19 ea

Order from Northern Hydraulic 800.556.7885 or

www.northerntool.com.

Remember that you'll need to pick up pressure on the outlet side somewhere...

Cheers Mark

*end of comment*

We were talking about brake lines a few days ago. I had concerns. I hate when my airplane won't stop. I had planned to use solid aluminum tubing from the firewall to the caliper as is done on other RVs, etc. I've never been wild about the Nylaseal stuff due to heat softening concerns so I didn't want to use it.

Then Jim Winings and Mark convinced me to take a look at using something other than solid aluminum lines. They explained to me that the world would end, the sky would fall, etc, and my brake lines would break... blah, blah, blah :-) Seriously though, I value their opinions and the change I'm gonna make is easy and cheap.

Here's what I found. Maybe this will cause others to rip out their finished brake lines and set themselves back a week. LOL

Aeroquip makes a teflon lined S/S hose, FC807-4, that is equivalent to their teflon lined S/S brake (racing)hose. They told me so on the phone, although they really can't say that. The difference is that FC807-4 is $1.20/ft and the racing hose is $4/ft. They use the same fittings.

http://aeroquip.murdockindustrial.com/hoseselector.htm One supplier. In Ohio. The kid was quite helpful.

https://fluidpower.eaton.com/intradoc/groups/public/documents/prod_bulletins/ja886.pdf Specs for the hose. In a nutshell, -100 to 450 degrees, operating pressure 3000 psi, and burst at 12,000 psi. 0.06 pounds per ft

I bought enough line to and fittings to make every part of the brake line, both sides, and it was only about $70. Cheap. And the fittings are easy to install and reusable.

Racer Parts Wholesale - Racing Parts And Accessories http://www.racerpartswholesale.com/ Bob Japundza recommends these guys for Aeroquip stuuf at a reasonable price. They're in Indianapolis.

Unscientific hose price comparison…. YMMV!

I bought all of my hose and fittings from Murdock Industrial. They didn't pay me to say this, nor are they the cheapest industrial supplier online. They just happened to be close to me and had an 800 phone number.

I bought industrial teflon hose that should last forever and has the same specs as the Aeroquip 666 hose. The industrial teflon hose is p/n FC807-04, or -06, or -08. Price is $4.51/ft and $5.49/ft for the -06 and -08 respectively. I don't have the -04 price handy, but it was less than $4/ft IIRC. Compare these prices to the ACS price of $5.80, $8.30, and $10.55 per foot for their 666 hose in -04, or -06, or -08.

I used steel fittings. Sure they weigh more, but I'm more comfortable with their toughness. Straight hose end fittings for the teflon hose are p/n 63-190600-04 ($4.16 ea), p/n 63-190600-06 ($5.31 ea), p/n 63-190600-08 ($7.05 ea). ACS price for their teflon hose fittings are $14.97 for -04, $16.90 for -06, and $15.85 for -08.

A 45 degree hose end is $8.72 and a 90 degree hose end is $7.93 from Murdock. They aren't available for the 666 hose from ACS.

Their industrial firesleeve was much cheaper also. -04 $6.00/ft vs $0.62/ft, -06 $7.60/ft vs $0.68/ft, and for the -08 $9.20/ft vs $0.84/ft. HOWEVER, the aviation firesleeve is heavier than the industrial stuff, i.e. it has more fiberglass inside. Nonetheless, I plan to use the industrial stuff in most places. On the outside it is the same RTV red as the aviation stuff.

The DEL 37 degree seals (also called JIC seals) were more expensive from Murdock. About double. But since you don't really need these anyway unless you're reusing old fittings, it's rather moot.

The miscellaneaous AN to pipe fittings were much cheaper from Murdock. I'm not going to list them since there are a zillion of them.

I added up the cost to buy one of each item from ACS and the equivalent industrial item from Murdock. The result was $151 from ACS and $47 from Murdock. A savings of roughly 66%

Like I said, YMMV. If you're comfortable weeding through the industrial stuff, you can save a pretty fair amount of money. Even if you only used the industrial teflon hose and fittings, you'll save a ton and it is vastly easier to assemble than the Aeroquip 303 hose you often see in airplanes.

If somebody can offer a comparison of industrial vs racing components, it would be interesting to know the difference. JEG's prices anyone?

(This is usually about where Japundza steps in and tells me about how he got his parts for half of what I paid. And it included a lap dance and free NASCAR tickets. I'm starting to really hate him. LOL ) Build on! Vince Frazier

Here's one way to pressure test the hoses you make. The hydraulic pump

came from Tool Central. I think I've seen them at Harbor Freight also.

With a few AN fittings and some AN plugs for the end of the hose being tested

you can easily test your hoses. The second photo shows a fuel line

being tested. If the fuel line only gets 30 psi in service, testing it to

500 psi should be good enough! I let 'em set under pressure for several

minutes then check for leaks or significant pressure drop.... or both!

Here's one way to pressure test the hoses you make. The hydraulic pump

came from Tool Central. I think I've seen them at Harbor Freight also.

With a few AN fittings and some AN plugs for the end of the hose being tested

you can easily test your hoses. The second photo shows a fuel line

being tested. If the fuel line only gets 30 psi in service, testing it to

500 psi should be good enough! I let 'em set under pressure for several

minutes then check for leaks or significant pressure drop.... or both!

There is enough hydraulic fluid in the pump to test most hoses. Let the fluid drain back into the pump after each test. This rig works great and is highly recommended for hose testing and peace of mind. Vince *end of comment*

Fuel Pump Clearance:

The fuel pump overflow vent fitting interferes with the firewall. So you either have to move the vent or move the fitting. Tom Martin describes both techniques. Moving the fitting is by far the easiest since it only involves drilling and tapping a hole, not disassembling the entire pump. Vince

I mounted my engine today, twice. The first time everything went well until I discovered that the overflow vent from the engine mounted fuel pump contacted the firewall. In the RV's and Harmon's, it has been close, but it did not hit. A call to Mark confirmed that yes it is something that needed to be modified. Here is the procedure that worked for me and was suggested by Mark

1.You need to take the engine off the airplane.

2.Remove the fuel pump from the engine. When the pump is loose turn the engine over so that there is the least amount of pressure on the pump, this will make reassembly easier.

3. There are a number of screws on the body of the pump, small ones on top, and long ones on the bottom. Mark the body of the pump and remove the screws.

4. Turn the offending part clockwise so that vent lines up with the out port of the pump.

5. You may have to remove a little material from the top of the out port so that the two parts will not bind.

6. Clamp the pump together so that the holes align.

7. Drill through the holes and replace the screws with AN3-23A bolts and self locking metal nuts.

8. One of the screws will be retained on the underside close to the engine and should have locktite applied.

9. Remount the engine.

PS. The proper engine mount bolts are AN7-35A not 36A. (Unless you needed a shim! Vince )

Tom Martin *end of comment*

Tom's other technique (words and photo by Vince) Rather than disassemble the pump so the vent port would clear the firewall, I did the following: the vent was plugged with a pipe plug. I had to trim the bottom of the pipe plug to clear the hose barb. I tapped a hole in the side of the overflow vent and installed a hose barb for the overflow line. Be sure to put a piece of foam inside the vent port while drilling and tapping to keep the chips out of the pump. And clean out all of the foam and chips before the final assembly... duh. I used JB Weld to seal/glue the hose barb in place since there is no way to safety it and my tapped hole was just a little loose. Not shown in the picture was the final grinding off of the pipe plug so that no excess metal was left sticking out. Vince FrazierEngine related service bulletins and ADs

Be sure to check for newer revisions!!! Just because it's here doesn't make it so!

Lycoming home page: http://www.lycoming.textron.com

Service Bulletin main page:

http://www.lycoming.textron.com/main.jsp?bodyPage=support/publications/maintenancePublications/serviceBulletins.html

Fuel injection service bulletin page: http://www.lycoming.textron.com/support/publications/maintenancePublications/serviceBulletins/SB342D.pdf

Here's the AD that refers to the SB above.

93-02-05 TEXTRON LYCOMING: Amendment 39-8487. Docket 92-ANE-56.

Applicability: Textron Lycoming reciprocating opposed piston engines

incorporating fuel injection lines as

listed in Textron Lycoming Service Bulletin No. (SB) 342A, dated May 29, 1992,

except for Model

TIO-540-S1AD engines. Affected engine models are installed on but not limited to

Piper PA-24 Comanche, PA-30

and PA-39 Twin Comanche, PA-28 Arrow, and PA-23 Aztec; Beech 60 Duke and 23

Musketeer; Mooney M20;

and Cessna 177 Cardinal aircraft.

NOTE: Engines with an "I" in the prefix of the model designation incorporate

fuel injection.

Compliance: Required as indicated, unless accomplished previously.

To prevent failure of the fuel injector fuel lines allowing fuel to spray into

the engine compartment, resulting

in an engine fire, accomplish the following:

(a) Within 25 hours time in service after the effective date of this AD, inspect

the fuel injector fuel lines

between the fuel manifold and the fuel injector nozzles in accordance with

Textron Lycoming Service Bulletin

No. 342A, dated May 26, 1992.

(b) Prior to further flight, replace any fuel injector fuel line that does not

meet all the return to service

conditions specified in Textron Lycoming SB No. 342A, dated May 26, 1992.

(c) Thereafter, at each annual inspection, at each 100-hour inspection, at each

engine overhaul, and after

any maintenance has been performed on the engine where the fuel injector fuel

lines have been disconnected, moved,

or loosened, reinspect the fuel injector fuel lines in accordance with Textron

Lycoming SB No. 342A, dated

May 26, 1992, and replace as necessary any fuel injector fuel line that does not

meet all the return to service

conditions specified in that SB.

(d) An alternative method of compliance or adjustment of the compliance time

that provides an acceptable

level of safety may be used if approved by the Manager, New York Aircraft

Certification Office. The request

should be forwarded through an appropriate FAA Maintenance Inspector, who may

add comments and then send it

to the Manager, New York Aircraft Certification Office.

NOTE: Information concerning the existence of approved alternative methods of

compliance with this

airworthiness directive, if any, may be obtained from the New York Aircraft

Certification Office.

(e) Special flight permits may be issued in accordance with FAR 21.197 and

21.199 to operate the

airplane to a location where the requirements of this AD can be accomplished.

(f) The inspection, and replacement, if necessary of the fuel injector fuel

lines shall be done in accordance

with the following service document:

Document No. Pages Date

Textron Lycoming SB

No. 342A 1-31 May 26, 1992

Total pages: 31

This incorporation by reference was approved by the Director of the Federal

Register in accordance with

5 U.S.C. 552(a) and 1 CFR Part 51. Copies may be obtained from Textron Lycoming

Reciprocating Engine

Division, 652 Oliver Street, Williamsport, Pennsylvania 17701. Copies may be

inspected at the FAA, New

England Region, 12 New England Executive Park, Burlington, Massachusetts; or at

the Office of the Federal

Register, 800 North Capitol Street, NW., suite 700, Washington, DC.

(g) This amendment becomes effective on June 14, 1993.

Engine Trivia:

Firing order: Lycoming's Direct Drive engine overhaul manual ,

Section 4 -Ignition system 4-5. Engine firing order.4 cylinder engines (except

LIO series) 1-3-2-4 . LIO series 1-4-2-3.

6 cylinder engines 1-4-5-2-3-6. LIO series 1-6-3-2-5-4.

8 cylinder engines 1-5-8-3-2-6-7-4 . *end of comment*

I am using fuel filters ordered from Jeg's Hi

Performance Auto (800-345-4545) and really like them. They are high

quality Aluminum with stainless steel interior, reusable and come with AN-6

fittings. They handle my max fuel flow (about 28 GPH on takeoff) with no

problem and measure 2''X4''. P/N is 888-201406. Name is System-One

Prostreet. Cost is about $90 each, but you will use them the life of the

aircraft. Jim Cash

*end of comment*

Q: What quantity and length, type of fittings, etc., do we need?

A: I buy all my hose fabrication parts from Summit Racing. I get the Aeroquip parts -- not the Earl's brand. I buy their AQP hose, and auto-fit ends. No mandrel is necessary, but I recommend getting their aluminum jaws for your vise (for hose assy). Mark Frederick

Q:. Hoses for the Oil cooler?

A: -8 size here, again all straight ends. Buy 3' of hose, and cut to fit your installation. You'll need adapter fittings for the cooler itself, along with fittings to screw into the back of the accy case of the engine. Mark Frederick

Q: Hoses for the Air/oil separator?

A: I used cloth braided hose here -- I recall getting it from Wicks (this hose installs with hose clamps, not ends) Mark Frederick

Q: Any other hoses needed! i.e., from the fuel pump to the firewall AN fitting?

A: -6 size here. The ends vary, and I recommend a length of hose to connect the pump outlet to the firewall bulkhead fitting. Use firesleeve on this hose! You'll need -4 hose to run from the throttle body up to the flow divider too. Mark Frederick *end of comment*

Q: What kind of spacer/washer is needed for the inner motor mount bolts at the firewall?

A: You are referring to the inner two bolts that attach the upper ends of the leg sockets to the firewall, right? Luis Escobar gave me some SS washers to pass out, but I doubt the thickness is right for very many applications. You can make your own from aluminum scrap, or you can look for a selection of washers that will do the job. Shim this area exactly correctly!! Mark Frederick *end of comment*

Q: Anyone know the Lord p/n's for a HRII?A: J9613-12, John Harmon

*end of comment* When the Super 6 was built in early '98, the Barry folks recommended p/n 94016-02 (Maule M-6-235) as an aerobatic mount. Currently, John Harmon recommends the Mooney M20F mount, Lord #J-9613-12, Barry #94011-02.These can be ordered from AC$pruce. Lord has come out with a new set of aerobatic mounts, #J-7764-31, that are supposed to handle side loading better. The Northern Lights team uses these mounts. http://www.lordcorp.com

My Barry mounts were deforming after 3 yrs/313 hrs. and the engine sag was about an 1/8", just enough for the alternator pulley to start kissing the inside bottom cowl. Boyd Braem, RV-Super 6/IO-540 *end of comment*

Is everyone aware that the shock mounts for dynafocal mount Lycs have one rubber biscuit that is harder than the other at all four positions? You have to install them so that the weight of the engine when sitting on the ground rests on the hard biscuit. This means that for the top mounts, the hard biscuit has to be on the aft side of the engine mount and on the bottom mounts the hard ones have to be on the forward side of the mount. I can't tell you the number of airplanes I have seen over the years with them reversed, or even random. If you do reverse them, the soft mounts will take a set and the engine will sag over time. From the RV list *end of comment*

Q: Help?? Someone tell me the exact engine id numbers that will fit the F-1 before I go buy a monument for my front yard!!!!A: OK: you'll need an injected parallel valve engine with the heavy counterweights and the large mount ears. If you plan to OH a run-out, almost any will work as a start point. If you want to bolt-in a mid-time, look for a C4B5. There are many options in between, too. Now, you can change counterweights if you find a good deal on the wrong type. Likewise, you can add FI to a carb equipped type, or change the mount ears too. We're lucky in that we can shop from a wide range, to get to the final type we need. Mark Frederick

*end of comment* The term "wide-deck" and "narrow-deck" have nothing to do with the valve drive train (angle valve vs. parallel valve). All angle valve engines are wide-deck and so are the new parallel-valve engines. The difference between wide-deck and narrow-deck engines is in the cases and the cylinder base flanges. Basically, the case is heavier and the flange of the cylinder where it bolts to the case is heavier. The engine is slightly wider. Narrow-deck engines are slightly lighter, and narrower by some small amount. Lycoming switched all their engines to this design I think in the early 70's, but model designations did not change. They changed the design because of crankcase fretting problems related to improperly torqued cylinders. For example, the C4B5 was/is built in both varieties, and only the serial numbers are different. It's easy to tell the difference between the two. A narrow-deck engine has internally toothed cylinder hold-down nuts and backup-flanges. A wide-deck engine has thicker bases without the backup flanges, and regular hex nuts that go on the studs that hold the cylinders down.I use a high pressure Dukes fuel pump mounted just aft of the firewall. This is a direct flow unit, by that I mean that no bypass plumbing is required. During use it puts out 26 psi, and when off the engine driven pumps shows 23 psi. I use the boost pump for starts, take offs landings and when changing fuel tanks. I have close to 1000 hours using this type of pump on three airplanes, with no problems at all. Tom Martin

*end of comment* I hear some are using the Dukes pumps, but I have Airflow Performance pumps on my ships. These have a bypass feature (in the event of certain modes of boost pump failure), and cost only $375. I suspect the certified Dukes is $500+?The fuel schematic is from Airflow performance, the text description Mark gave on vents is helpful.

If you buy the whole AFP system ($2560 for ALL the parts required to install an FI system on the F1, down to the elbow w/ adapter & drain valve, injector line clamps, & screws!), the pump is included for substantially less.

A new AFP throttle body runs $1250 -- and give more torque too. Keep this price in mind when considering an O/H for your Bendix. If the upper parts (lines & flow divider) are OK, these will work with the AFP throttle body.

Throttle Body elbows: Of course, you all know you will need one of these, to get the throttle body laid fwd as required by the intake design. Plan on adding $219 to the price of the AFP throttle body (these parts are included in the kit), and plan on $122 for the elbow to fit the Bendix.

I

f you are using the Bendix, get the 95 deg elbow with the drain valve. If you will be using the AFP system, get the 5 deg adapter too. You can order direct from AFP. Talk to Colleen Rivera at 864.576.4512. Order p/n 3010081 elbow ($105) with 1090138 drain valve ($17), and get some gaskets too (p/n 1010059). You can make a throttle/mixture cable attach bracket that attaches to the sump above the elbow if desired. Cheers MarkAnd then there is the Christen wobble pump, which can serve as a boost pump. ACS carries these. Mark Frederick *end of comment*